Material:

Grösse:

Verlag:

Jahrgang:

Auflage:

ISBN:

Zustand:

Preis:

Material:

Grösse:

Verlag:

Jahrgang:

Auflage:

ISBN:

Zustand:

Preis:

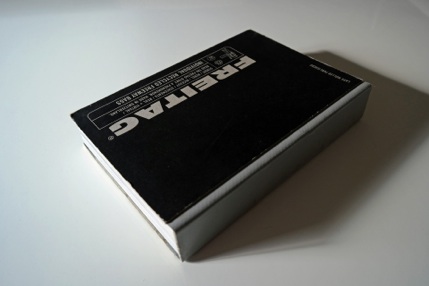

Buch: FREITAG - Indiv. Recycled Freeway Bags

Buchrücken: Lastwagenblache hellgrau

Front und Backcover: Karton schwarz

Seiten: farbig mit Bild und Text

245 x 170 x 45mm

Lars Müller Publishers, Baden/CH

www.lars-mueller-publishers.com/de/

2001

1.Auflage, 10‘000 Stück, Vergriffen!

3-907078-47-0

gebraucht, leichte Gebrauchsspuren an Deckelkanten

CHF 64.00

Weitere Fotos und Informationen sind auf Wunsch

jederzeit erhältlich.

Zusatzinformationen zu diesem Objekt:

Lars Müller Publishers, Baden/CH

www.lars-mueller-publishers.com/de/

THE HISTORY OF THE UNIQUE FREITAG BAG

Back in 1993, graphic designer brothers Markus and Daniel Freitag were on the lookout for a messenger bag. Zurich citizens worthy of the name travel by bicycle - 'velo,' they call it. When it rains, they get wet. The FREITAG brothers wanted a heavy-duty, functional and water-repellent bag to carry their designs. Inspired by the cheerfully coloured lorries rumbling along the cross-Zurich highway just in front of their flat, they cut a messenger bag out of an old truck tarpaulin. As the carry belt, they used second-hand car seat-belt webbing, while an old bicycle inner tube provided the edging.

As luck would have it, their personal need turned into a business which now employs more than 80 people. Since their original messenger bag, the FREITAG brothers have developed and marketed more than 40 bags for women and men. FREITAG products now sell round the globe, in over 300 shops, at our online webshop and in our FREITAG shops in Berlin, Davos, Hamburg, Cologne and Zurich. They continue to be made in Switzerland, beside the cross-city highway which inspired them in 1993.

You can't teach an old dog new tricks.

FREITAG has been manufacturing bags and accessories for women and men since 1993. Our materials are used, having seen service on the road. They are well-travelled truck tarpaulins, unravelled seat belts, bicycle inner tubes beyond repair, recycled airbags. Tough stuff - which makes our products tough, too. As for us, we are Swiss, which means we are acutely quality-conscious. We apply our recycled materials in a totally new way, insisting on superlative design and functionality. Every FREITAG product is made from original tarpaulins of different colours, markings and contours. So every FREITAG product is a one-off.

FREITAG bags are on sale at our online shop, in our FREITAG Flagship Shops (Berlin, Davos, Hamburg, Cologne and Zurich) and in 300 shops round the world.

HOW TO CREATE?

The FREITAG FACTORY in downtown Zurich, Switzerland, used to be a shed belonging to Maag Zahnräder AG (gear systems weighing several tons for ocean-going ships and similar applications). Today a crew of nearly 80 work here, in 2800 square metres of space, in production, logistics and administration in and over the warehouse. FREITAG is proud to be one of the last industrial companies still in production in the city centre. Here's how a used truck tarpaulin turns into a new FREITAG bag.

First, we have to find fine used truck tarpaulins, for which we negotiate with haulage companies Europe-wide. Normally used tarpaulins are costly to dispose of but, for FREITAG, they are an important raw material. As soon as truck tarpaulins are replaced anywhere, we buy up the old ones. The more cheerful the colours, the better.

Then the bulky truck tarps must be divided into wearable pieces. It's dirty, heavy, hard work for FREITAG. Then we wash the pieces in our XXXL washing machines. The humming is hypnotic.

Washed and combed (brushed flat), the tarpaulins are hand-cut around transparent templates using a cutter knife. Our designers use transparent templates because they have to decide which cutting looks best on the future bag. The individual cut-outs are put together, sometimes rearranged, and clipped together. Now they are ready to be made up into a FREITAG bag. The individual fronts, sides, backs and bottoms are arranged, sometimes rearranged and clipped together. They are now ready to become a bag.

The joined pieces are sent out to sewing workshops selected by FREITAG in Switzerland, France, Portugal and Tunisia. These machinists specialize in seaming our heavy-duty materials. Finally the made-up product returns to us. We check it, take a photograph (because every one is different) and pack it. Then out it goes into the wide world.

All this is the work that goes into your FREITAG bag.

(Quelle: http://www.freitag.ch)